- MLB

- Arizona Diamondbacks transfer

- Atlanta Braves transfer

- Baltimore Orioles transfer

- Boston Red Sox transfer

- Chicago Cubs transfer

- Chicago White Sox transfer

- Cincinnati Reds transfer

- Cleveland Guardians transfer

- Cleveland Indians transfer

- Colorado Rockies transfer

- Detroit Tigers transfer

- Houston Astros transfer

- Kansas City Royals transfer

- Los Angeles Angels transfer

- Los Angeles Dodgers transfer

- Miami Marlins transfer

- Milwaukee Brewers transfer

- Minnesota Twins transfer

- New York Mets transfer

- New York Yankees transfer

- Oakland Athletics transfer

- Philadelphia Phillies transfer

- Pittsburgh Pirates transfer

- San Diego Padres transfer

- San Francisco Giants transfer

- Seattle Mariners transfer

- St. Louis Cardinals transfer

- Tampa Bay Rays transfer

- Texas Rangers transfer

- Toronto Blue Jays transfer

- Washington Nationals transfer

- Major League Baseball transfer

- MLB All-Star Game transfer

- MLB Batman transfer

- MLB Draft transfer

- MLB Halloween transfer

- MLB Opening Day transfer

- MLB Postseason transfer

- MLB Star Wars transfer

- MLB Superman transfer

- MLB USA Flags transfer

- NBA

- Atlanta Hawks transfer

- Boston Celtics transfer

- Brooklyn Nets transfer

- Charlotte Hornets transfer

- Chicago Bulls transfer

- Cleveland Cavaliers transfer

- Dallas Mavericks transfer

- Denver Nuggets transfer

- Detroit Pistons transfer

- Golden State Warriors transfer

- Indiana Pacers transfer

- Los Angeles Clippers transfer

- Los Angeles Lakers transfer

- Memphis Grizzlies transfer

- Miami Heat transfer

- Milwaukee Bucks transfer

- Minnesota Timberwolves transfer

- New Orleans Pelicans transfer

- New York Knicks transfer

- Oklahoma City Thunder transfer

- Orlando Magic transfer

- Philadelphia 76ers transfer

- Phoenix Suns transfer

- Portland Trail Blazers transfer

- Sacramento Kings transfer

- San Antonio Spurs transfer

- Toronto Raptors transfer

- Utah Jazz transfer

- Washington Wizards transfer

- National Basketball Association transfer

- NBA All-Star Game transfer

- NBA Batman transfer

- NBA Eastern Conference transfer

- NBA Finals transfer

- NBA Franchise transfer

- NBA Halloween transfer

- NBA Playoffs transfer

- NBA Pokemon transfer

- NBA Rappers transfer

- NBA Super Heroes transfer

- NBA Superman transfer

- NBA USA Flags transfer

- NBA Video Games transfer

- NBA Western Conference transfer

- NFL

- Arizona Cardinals transfer

- Atlanta Falcons transfer

- Baltimore Ravens transfer

- Buffalo Bills transfer

- Carolina Panthers transfer

- Chicago Bears transfer

- Cincinnati Bengals transfer

- Cleveland Browns transfer

- Dallas Cowboys transfer

- Denver Broncos transfer

- Detroit Lions transfer

- Green Bay Packers transfer

- Houston Texans transfer

- Indianapolis Colts transfer

- Jacksonville Jaguars transfer

- Kansas City Chiefs transfer

- Los Angeles Chargers transfer

- Los Angeles Rams transfer

- Miami Dolphins transfer

- Minnesota Vikings transfer

- New England Patriots transfer

- New Orleans Saints transfer

- New York Giants transfer

- New York Jets transfer

- Oakland Raiders transfer

- Philadelphia Eagles transfer

- Pittsburgh Steelers transfer

- San Francisco 49ers transfer

- Seattle Seahawks transfer

- Tampa Bay Buccaneers transfer

- Tennessee Titans transfer

- Washington Commanders transfer

- Washington Redskins transfer

- American Football Conference transfer

- National Football Conference transfer

- National Football League transfer

- NFL Anime transfer

- NFL Batman transfer

- NFL British transfer

- NFL Butts transfer

- NFL Canadian transfer

- NFL Disney transfer

- NFL Draft transfer

- NFL Fat transfer

- NFL Game Of Thrones transfer

- NFL Halloween transfer

- NFL Heavy Metal transfer

- NFL Hipsters transfer

- NFL Iconic Food transfer

- NFL Manning transfer

- NFL Patriotic transfer

- NFL Playoffs transfer

- NFL Skull transfer

- NFL Smoking Weed transfer

- NFL Steroids transfer

- NFL Superman transfer

- NFL Swapped transfer

- NFL USA Flags transfer

- NFL Wrestlers transfer

- Pro Bowl transfer

- Super Bowl transfer

- NHL

- Anaheim Ducks transfer

- Arizona Coyotes transfer

- Boston Bruins transfer

- Buffalo Sabres transfer

- Calgary Flames transfer

- Carolina Hurricanes transfer

- Chicago Blackhawks transfer

- Colorado Avalanche transfer

- Columbus Blue Jackets transfer

- Dallas Stars transfer

- Detroit Red Wings transfer

- Edmonton Oilers transfer

- Florida Panthers transfer

- Los Angeles Kings transfer

- Minnesota Wild transfer

- Montreal Canadiens transfer

- Nashville Predators transfer

- New Jersey Devils transfer

- New York Islanders transfer

- New York Rangers transfer

- Ottawa Senators transfer

- Philadelphia Flyers transfer

- Pittsburgh Penguins transfer

- San Jose Sharks transfer

- Seattle Kraken transfer

- St. Louis Blues transfer

- Tampa Bay Lightning transfer

- Toronto Maple Leafs transfer

- Vancouver Canucks transfer

- Vegas Golden Knights transfer

- Washington Capitals transfer

- Winnipeg Jets transfer

- Campbell Conference transfer

- National Hockey League transfer

- NHL All-Star Game transfer

- NHL Batman transfer

- NHL Draft transfer

- NHL Eastern Conference transfer

- NHL Entertainment transfer

- NHL Heritage Classic transfer

- NHL Pokemon transfer

- NHL Simpsons transfer

- NHL Stadium Series transfer

- NHL Superman transfer

- NHL USA Flags transfer

- NHL Western Conference transfer

- NHL Winter Classic transfer

- NHLPA transfer

- Stanley Cup Playoffs transfer

- Wales Conference transfer

- World Cup of Hockey transfer

- NCAA(a-b)

- Abilene Christian Wildcats transfer

- AIC Yellow Jackets transfer

- Air Force Falcons transfer

- Akron Zips transfer

- Alabama A&M Bulldogs transfer

- Alabama Crimson Tide transfer

- Alabama State Hornets transfer

- Alabama-Huntsville Chargers transfer

- Alaska Anchorage Seawolves transfer

- Alaska Nanooks transfer

- Albany Great Danes transfer

- Alcorn State Braves transfer

- American Eagles transfer

- Appalachian State Mountaineers transfer

- Arizona State Sun Devils transfer

- Arizona Wildcats transfer

- Arkansas Razorbacks transfer

- Arkansas State Red Wolves transfer

- Arkansas-Little Rock Trojans transfer

- Arkansas-PB Golden Lions transfer

- Army Black Knights transfer

- Auburn Tigers transfer

- Austin Peay Governors transfer

- Ball State Cardinals transfer

- Baylor Bears transfer

- Bellarmine Knights transfer

- Belmont Bruins transfer

- Bemidji State Beavers transfer

- Bentley Falcons transfer

- Bethune-Cookman Wildcats transfer

- Binghamton Bearcats transfer

- Birmingham-Southern Panthers transfer

- Boise State Broncos transfer

- Boston College Eagles transfer

- Boston University Terriers transfer

- Bowling Green Falcons transfer

- Bradley Braves transfer

- Brigham Young Cougars transfer

- Brown Bears transfer

- Bryant Bulldogs transfer

- Bucknell Bison transfer

- Buffalo Bulls transfer

- Butler Bulldogs transfer

- NCAA(c-d)

- Cal Poly Mustangs transfer

- Cal State Fullerton Titans transfer

- Cal State Northridge Matadors transfer

- California Baptist Lancers transfer

- California Davis Aggies transfer

- California Golden Bears transfer

- California Riverside Highlanders transfer

- California-Irvine Anteaters transfer

- Campbell Fighting Camels transfer

- Canisius Golden Griffins transfer

- Centenary Gentlemen transfer

- Central Arkansas Bears transfer

- Central Florida Knights transfer

- Central Michigan Chippewas transfer

- Charlotte 49ers transfer

- Chattanooga Mocs transfer

- Chicago State Cougars transfer

- Cincinnati Bearcats transfer

- Clarkson Golden Knights transfer

- Clemson Tigers transfer

- Cleveland State Vikings transfer

- Coastal Carolina Chanticleers transfer

- Colgate Raiders transfer

- College of Charleston Cougars transfer

- Colorado Buffaloes transfer

- Colorado College Tigers transfer

- Colorado State Rams transfer

- Columbia Lions transfer

- Coppin State Eagles transfer

- Cornell Big Red transfer

- Creighton Bluejays transfer

- CSU Bakersfield Roadrunners transfer

- CSU Buccaneers transfer

- Dartmouth Big Green transfer

- Davidson Wildcats transfer

- Dayton Flyers transfer

- Delaware Blue Hens transfer

- Delaware State Hornets transfer

- Denver Pioneers transfer

- DePaul Blue Demons transfer

- Detroit Titans transfer

- Dixie State Trailblazers transfer

- Drake Bulldogs transfer

- Drexel Dragons transfer

- Duke Blue Devils transfer

- Duquesne Dukes transfer

- NCAA(e-h)

- East Carolina Pirates transfer

- Eastern Illinois Panthers transfer

- Eastern Kentucky Colonels transfer

- Eastern Michigan Eagles transfer

- Eastern Washington Eagles transfer

- Elon Phoenix transfer

- ETSU Buccaneers transfer

- Evansville Purple Aces transfer

- Fairfield Stags transfer

- Fairleigh Dickinson Knights transfer

- Ferris State Bulldogs transfer

- FIU Panthers transfer

- Florida A&M Rattlers transfer

- Florida Atlantic Owls transfer

- Florida Gators transfer

- Florida Gulf Coast Eagles transfer

- Fordham Rams transfer

- Fresno State Bulldogs transfer

- Furman Paladins transfer

- Gardner-Webb Bulldogs transfer

- George Mason Patriots transfer

- George Washington Colonials transfer

- Georgetown Hoyas transfer

- Georgia Bulldogs transfer

- Georgia Southern Eagles transfer

- Georgia State Panthers transfer

- Georgia Tech Yellow Jackets transfer

- Gonzaga Bulldogs transfer

- Grambling State Tigers transfer

- Grand Canyon Antelopes transfer

- Hampton Pirates transfer

- Hartford Hawks transfer

- Harvard Crimson transfer

- Hawaii Warriors transfer

- High Point Panthers transfer

- Hofstra Pride transfer

- Holy Cross Crusaders transfer

- Houston Baptist Huskies transfer

- Houston Cougars transfer

- Howard Bison transfer

- NCAA(i-l)

- Idaho State Bengals transfer

- Idaho Vandals transfer

- Illinois Fighting Illini transfer

- Illinois State Redbirds transfer

- Illinois-Chicago Flames transfer

- Incarnate Word Cardinals transfer

- Indiana Hoosiers transfer

- Indiana State Sycamores transfer

- Iona Gaels transfer

- Iowa Hawkeyes transfer

- Iowa State Cyclones transfer

- IPFW Mastodons transfer

- IUPUI Jaguars transfer

- Jackson State Tigers transfer

- Jacksonville Dolphins transfer

- Jacksonville State Gamecocks transfer

- James Madison Dukes transfer

- Kansas Jayhawks transfer

- Kansas State Wildcats transfer

- Kennesaw State Owls transfer

- Kent State Golden Flashes transfer

- Kentucky Wildcats transfer

- La Salle Explorers transfer

- Lafayette Leopards transfer

- Lamar Cardinals transfer

- Lehigh Mountain Hawks transfer

- Liberty Flames transfer

- Lipscomb Bisons transfer

- Little Rock Trojans transfer

- LIU Sharks transfer

- LIU-Brooklyn Blackbirds transfer

- Long Beach State 49ers transfer

- Longwood Lancers transfer

- Louisiana Ragin Cajuns transfer

- Louisiana Tech Bulldogs transfer

- Louisiana-Monroe Warhawks transfer

- Louisville Cardinals transfer

- Loyola Marymount Lions transfer

- Loyola Ramblers transfer

- Loyola-Maryland Greyhounds transfer

- LSU Tigers transfer

- NCAA(m-n)

- Maine Black Bears transfer

- Manhattan Jaspers transfer

- Marist Red Foxes transfer

- Marquette Golden Eagles transfer

- Marshall Thundering Herd transfer

- Maryland Terrapins transfer

- Maryland-Eastern Shore Hawks transfer

- Massachusetts Minutemen transfer

- McNeese State Cowboys transfer

- Memphis Tigers transfer

- Mercer Bears transfer

- Mercyhurst Lakers transfer

- Merrimack Warriors transfer

- Miami (Ohio) Redhawks transfer

- Miami Hurricanes transfer

- Michigan State Spartans transfer

- Michigan Tech Huskies transfer

- Michigan Wolverines transfer

- Middle Tennessee Blue Raiders transfer

- Minnesota Golden Gophers transfer

- Minnesota State Mavericks transfer

- Minnesota-Duluth Bulldogs transfer

- Mississippi Rebels transfer

- Mississippi State Bulldogs transfer

- Missouri Tigers transfer

- Monmouth Hawks transfer

- Montana Grizzlies transfer

- Montana State Bobcats transfer

- Morehead State Eagles transfer

- Morgan State Bears transfer

- Mount St. Marys Mountaineers transfer

- Murray State Racers transfer

- MVSU Delta Devils transfer

- Navy Midshipmen transfer

- NC-Greensboro Spartans transfer

- NC-Wilmington Seahawks transfer

- NCCU Eagles transfer

- Nebraska Cornhuskers transfer

- Nebraska-Omaha Mavericks transfer

- New Hampshire Wildcats transfer

- New Mexico Lobos transfer

- New Mexico State Aggies transfer

- New Orleans Privateers transfer

- Nicholls State Colonels transfer

- NJIT Highlanders transfer

- Norfolk State Spartans transfer

- North Alabama Lions transfer

- North Carolina A&T Aggies transfer

- North Carolina State Wolfpack transfer

- North Carolina Tar Heels transfer

- North Dakota Fighting Hawks transfer

- North Dakota Fighting Sioux transfer

- North Dakota State Bison transfer

- North Texas Mean Green transfer

- Northeastern Huskies transfer

- Northern Arizona Lumberjacks transfer

- Northern Colorado Bears transfer

- Northern Illinois Huskies transfer

- Northern Iowa Panthers transfer

- Northern Kentucky Norse transfer

- Northern Michigan Wildcats transfer

- Northwestern State Demons transfer

- Northwestern Wildcats transfer

- Notre Dame Fighting Irish transfer

- NCAA(o-r)

- Oakland Golden Grizzlies transfer

- Ohio Bobcats transfer

- Ohio State Buckeyes transfer

- Oklahoma Sooners transfer

- Oklahoma State Cowboys transfer

- Old Dominion Monarchs transfer

- Oral Roberts Golden Eagles transfer

- Oregon Ducks transfer

- Pacific Tigers transfer

- Penn Quakers transfer

- Penn State Nittany Lions transfer

- Pepperdine Waves transfer

- Pittsburgh Panthers transfer

- Portland Pilots transfer

- Portland State Vikings transfer

- Prairie View A&M Panthers transfer

- Presbyterian Blue Hose transfer

- Princeton Tigers transfer

- Providence Friars transfer

- Purdue Boilermakers transfer

- Quinnipiac Bobcats transfer

- Radford Highlanders transfer

- Rhode Island Rams transfer

- Rice Owls transfer

- Richmond Spiders transfer

- Rider Broncs transfer

- RIT Tigers transfer

- Robert Morris Colonials transfer

- RPI Engineers transfer

- Rutgers Scarlet Knights transfer

- NCAA(s)

- Sacramento State Hornets transfer

- Sacred Heart Pioneers transfer

- Saint Francis Red Flash transfer

- Saint Louis Billikens transfer

- Saint Marys Gaels transfer

- Sam Houston State Bearkats transfer

- Samford Bulldogs transfer

- San Diego State Aztecs transfer

- San Diego Toreros transfer

- San Francisco Dons transfer

- San Jose State Spartans transfer

- Santa Clara Broncos transfer

- Savannah State Tigers transfer

- SE Missouri State Redhawks transfer

- Seattle Redhawks transfer

- Seton Hall Pirates transfer

- Siena Saints transfer

- SIU Edwardsville Cougars transfer

- South Alabama Jaguars transfer

- South Carolina Gamecocks transfer

- South Carolina State Bulldogs transfer

- South Dakota Coyotes transfer

- South Dakota State Jackrabbits transfer

- South Florida Bulls transfer

- Southeastern Louisiana Lions transfer

- Southern California Trojans transfer

- Southern Illinois Salukis transfer

- Southern Jaguars transfer

- Southern Methodist Mustangs transfer

- Southern Miss Golden Eagles transfer

- Southern Utah Thunderbirds transfer

- Southwest Missouri State Bears transfer

- St. Bonaventure Bonnies transfer

- St. Cloud State Huskies transfer

- St. Francis Terriers transfer

- St. John's Red Storm transfer

- St. Joseph's Hawks transfer

- St. Peters Peacocks transfer

- St. Thomas Tommies transfer

- Stanford Cardinal transfer

- Stephen F. Austin Lumberjacks transfer

- Stetson Hatters transfer

- Stony Brook Seawolves transfer

- Syracuse Orange transfer

- NCAA(t-z)

- Tarleton Texans transfer

- TCU Horned Frogs transfer

- Temple Owls transfer

- Tennessee State Tigers transfer

- Tennessee Tech Golden Eagles transfer

- Tennessee Volunteers transfer

- Tennessee-Martin Skyhawks transfer

- Texas A&M Aggies transfer

- Texas A&M-CC Islanders transfer

- Texas Longhorns transfer

- Texas Southern Tigers transfer

- Texas State Bobcats transfer

- Texas Tech Red Raiders transfer

- Texas-Arlington Mavericks transfer

- Texas-Pan American Broncs transfer

- Texas-SA Roadrunners transfer

- The Citadel Bulldogs transfer

- Toledo Rockets transfer

- Towson Tigers transfer

- Troy Trojans transfer

- Tulane Green Wave transfer

- Tulsa Golden Hurricane transfer

- UAB Blazers transfer

- UCLA Bruins transfer

- UConn Huskies transfer

- UCSB Gauchos transfer

- UMass Lowell River Hawks transfer

- UMBC Retrievers transfer

- UMKC Kangaroos transfer

- UNC Asheville Bulldogs transfer

- UNF Ospreys transfer

- Union Dutchmen transfer

- UNLV Rebels transfer

- USC Upstate Spartans transfer

- Utah State Aggies transfer

- Utah Utes transfer

- Utah Valley Wolverines transfer

- UTEP Miners transfer

- UTRGV Vaqueros transfer

- Valparaiso Beacons transfer

- Valparaiso Crusaders transfer

- Vanderbilt Commodores transfer

- Vermont Catamounts transfer

- Villanova Wildcats transfer

- Virginia Cavaliers transfer

- Virginia Commonwealth Rams transfer

- Virginia Tech Hokies transfer

- VMI Keydets transfer

- Wagner Seahawks transfer

- Wake Forest Demon Deacons transfer

- Washington Huskies transfer

- Washington State Cougars transfer

- Weber State Wildcats transfer

- West Virginia Mountaineers transfer

- Western Carolina Catamounts transfer

- Western Illinois Leathernecks transfer

- Western Kentucky Hilltoppers transfer

- Western Michigan Broncos transfer

- Wichita State Shockers transfer

- William and Mary Tribe transfer

- Winston-Salem State Rams transfer

- Winthrop Eagles transfer

- Wisconsin Badgers transfer

- Wisconsin-Green Bay Phoenix transfer

- Wisconsin-Milwaukee Panthers transfer

- Wofford Terriers transfer

- Wright State Raiders transfer

- Wyoming Cowboys transfer

- Xavier Musketeers transfer

- Yale Bulldogs transfer

- Youngstown State Penguins transfer

- Custom

- 3D High Density Iron-on Transfer Stickers

- Anti-Sublimation Iron-on Transfer Stickers

- Canvas Shoes Iron-on Transfer Stickers

- Care Label Iron-on Transfer Stickers

- Decorative Vinyl

- EVA PE Iron-on Transfer Stickers

- Flock Iron-on Transfer Stickers

- Flock Iron-on Transfers

- Foil Iron-on Transfer Stickers

- Glitter Iron-on Transfer Stickers

- Glitter Iron-on Transfers

- Glow in Dark Iron-on Transfers

- Glow In The Dark Iron-on Transfer Stickers

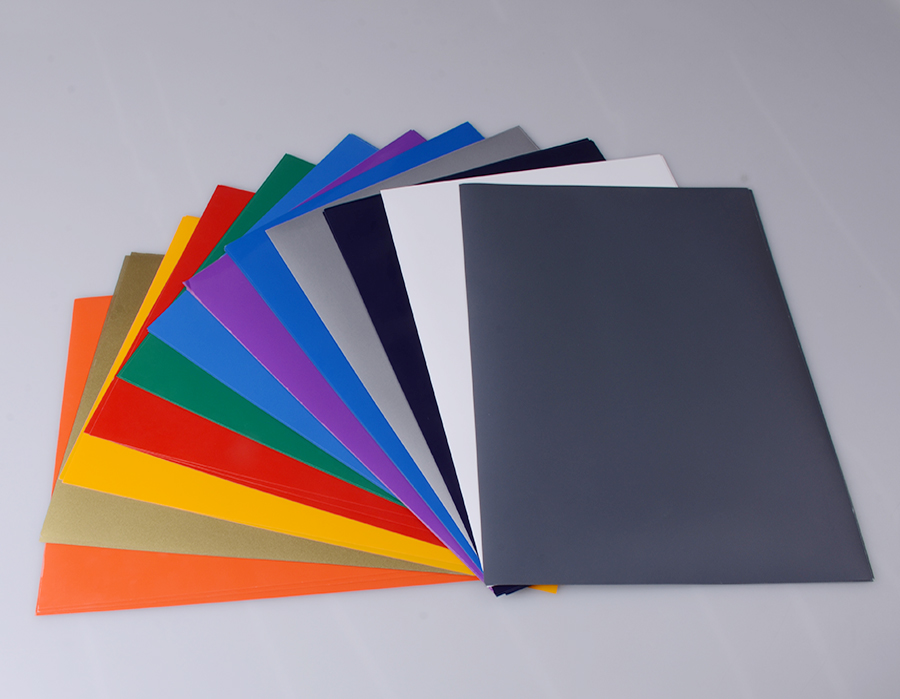

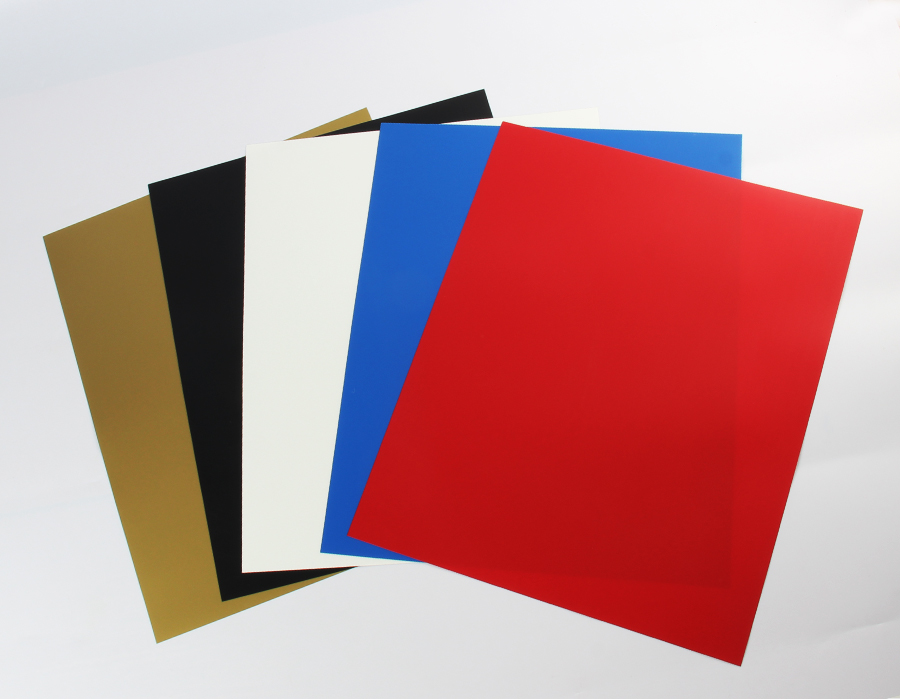

- Heat Transfer Vinyl

- Heat Transfer Vinyl Sheets

- Hologram Iron-on Transfers

- Hot Fix Rhinestone Iron-on Transfer Stickers

- Hot Fix Sequen Iron-on Transfer Stickers

- Laser Iron-on Transfer Stickers

- Leather Grain Iron-on Transfer Stickers

- Leather Iron-on Transfer Stickers

- Letter Number Iron-on Transfer Stickers

- Matte PU Iron-on Transfers

- Metallic Iron-on Transfers

- Nonwoven Iron-on Transfer Stickers

- Offset Iron-on Transfer Stickers

- Plastisol Iron-on Transfer Stickers

- Printable HTV Iron-on Transfers

- Printable Vinyl

- Puff Iron-on Transfer Stickers

- PVC Iron-on Transfer Stickers

- Reflective Iron-on Transfer Stickers

- Reflective Iron-on Transfers

- Screen Iron-on Transfer Stickers

- Shoe Iron-on Labels

- Silicone Iron-on Labels

- Suitcase Iron-on Transfer Stickers

- Thermochromic Iron-on Transfer Stickers

- FAQs

- Instruction

|

New Products

·Glitter heat transfer vinyl use high-end PET which cut into same size materials through precision machine ,then made into vinyls. Description: Glitter heat transfer vinly use high-end PET which through precision machine devided into same size materials,then made into vinyls.these high-temperature-resistance PET vinyls will turn into glitter heat transfer vinly with hot melt glue and release glue.

Main Feature: ·Glitter heat transfer vinyl use high-end PET which cut into same size materials through precision machine ,then made into vinyls. ·The stereo sense is good,and glossy light,matting hand-feeling is a the biggest difference from other heat transfer vinyls. ·Doesn't need making plate,it will save much time and cost.

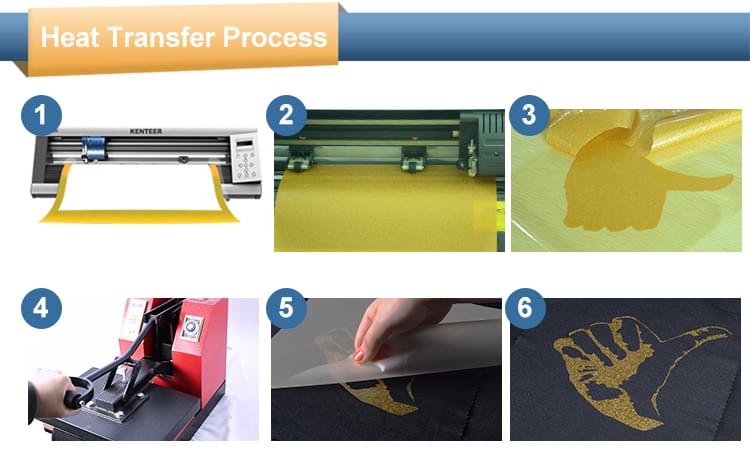

Instruction: ·Use cutting plotter divided into the shapes in need, tear away the film, cut depth between 10-30micron,cutting pressure 160-170gf is the best. ·Tear away the protect film,then transfer the picture cut onto fabrics through heat press machine. ·Transfer temperature 150-160degrees,10-15s,transfer pressure 20-30 LB. ·Peel the protect film after it turned cold.

Attention: ·The expiry date is within 12 months. ·try the simple then produce in massive. ·Seal the rest stickers,you should dry the products,don't let them in rainy day.

Add you TagsTAGS:What is DTF (direct to film) transfer?

DTF stands for Direct To Film. This printing process involves printing a design directly to a film, and transferring the design into a shirt or other substrates by using a heat press mechanism.

With DTF transfers, you can transfer designs of full colors on any kind of fabric whether it be cotton, polyester, or silk. Additionally, DTF transfers can be used to print on both dark and light-colored fabrics.

What will I receive after purchasing?

You will receive finished DTF transfers and an instruction in a package. All you need to prepare is a heat press machine and target/substrates/fabrics you are going to transfer onto.

How to use a heat press for DTF transfers?

Step 1: Preheat the heat press

Setting:

Temperature:160(°C)/320(°F)

Press time:20s

Pressure: 6kg

Step 2: Prepare the garment (Make sure it is flat and wrinkle-free)

Step 3: Position the DTF transfer (Make sure image facing up)

Step 4: Apply the heat press

Step 5: Hot peel the carrier sheet, all is done.

How do I make payment?

Currently we accept Credit Card.

How long do I get my orders?

For now there are 2 shipment options when you check out: (1) Normal Shipping: 1-2 business days to process your orders and another 7-15 business days to deliver; It will be FREE if you order more than US$30. (2) Fast Shipping: 1-2 business days to process your orders and another 3-5 business days to deliver; It will be FREE if you order more than US$80. Please check tracking information in your account for the status of your order.

Can I customize DTF transfers?

Sure, please send us your logos/designs, and tell us your quantity, size and other requests, we will feedback with links with price and proof for you to order.

How do you define size?

The size is defined vertically or horizontally which is longer.

Take some 4" logos for example, the below logos are defined as 4":

What discount can I get?

Dear customers, here are your discount coupons that you can apply: More than 30USD, normal shipping will be FREE. More than 80USD, expedited shipping will be FREE. Redemption Code for 10% off discount for at least 100USD: 100coupon Redemption Code for 15% off discount for at least 150USD: 150coupon Redemption Code for 20% off discount for at least 200USD: 200coupon Redemption Code for 30% off discount for at least 300USD: 300coupon Redemption Code for 35% off discount for at least 500USD: 500coupon Redemption Code for 40% off discount for at least 1500USD: 1500coupon Please type your Redemption Code into the box next to "Redemption Code" at the end of checking out. Your coupon will be applied to the total and reflected in your cart after you click update.

Contact us

Email/Skype:[email protected]

WhatsApp: +8618965078769

Similar Products |

||||||||||||||||||||||||||||||||||||||||||||||||

Email:[email protected]

WhatsAPP:+86 189 6507 8769

USA Address: 37 Forum Shopping Center Chesterfield MO 63017,USA

China Address:Floor 15,Sun Digital Building, Huangpu Road, Hi-Tech Zone, Xiamen,China (Mainland).

/02/Charlotte 49ers 2020-Pres Alternate Logo v3 iron on.png)

/01/Purdue Boilermakers 1996-2011 Alternate Logo diy iron on transfer 2.png)

/00/Oregon Ducks 1994-1998 Alternate Logo diy iron on transfer.png)